Scissor Lift Manufacturers In Thailand

LOADING / UNLOADING

IDEAL FOR LOADING / UNLOADING APPLICATIONS AT DIVERSE INDUSTRIAL, RETAIL AND COMMERCIAL ESTABLISHMENTS

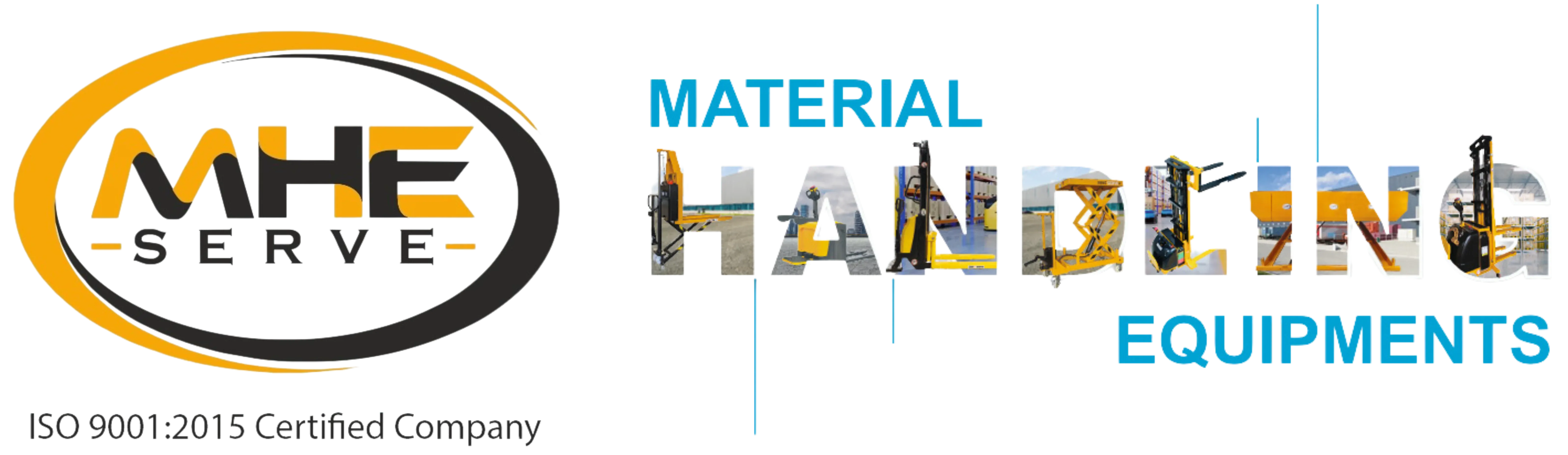

Scissor Lift Table are manufactured with wide range of customized models, such as Tandem Scissor Lift, Twin Scissor Lift, Double Scissor Lift, Single Scissor Lift, Movable Scissor Lifts and many more. This scissor lifts are primarily available with inching operations, but can be customized to different levels operations.

FEATURES:

Heavy duty and study equipment to save time and provide maximum productivity.

1. Heavy duty structure

2. Excellent smooth operation

3. Safety buzzer alarm

4. Safety overload protection

5. Safety stand for maintenance

6. Greasing nipple

HIGH RAISE SCISSOR WORK PLATFORM

STRONG AND STABLE EQUIPMENT FOR WORKING AT HEIGHTS.

“MHE SERVE” High Raise Scissor Aerial Working Platform are designed to provide ease of operations with maximum productivity and safety. Design are suited for weighted application upto 500 kgs & lift height upto 14000mm. It is a versatile equipment in mobile versions and are used for various applications mainly for doing maintenance work at higher height with utmost safety. These products are high-performance systems that operate at the touch of a button along with emergency stop switch with key and LED buzzer for operation alert and heavy duty powerpack. It is designed & constructed as per the Standards to suit the requirement of safety and maintenance free operations.

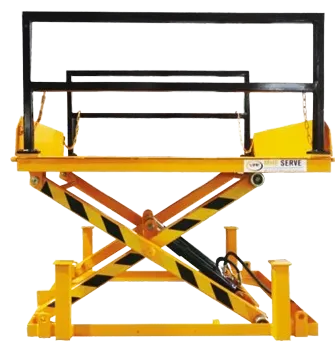

Capacity

9000 / 12000 and 15000 Kg

Split Lip Arrangement

A unique split lip design, suitable for varied truck widths

Tilt Facility

Compensate canted conditions when the truck is titled due to uneven weight loads, avoiding tyre damage while ensuring safe operations

4 Button operating panel & power pack system

Deck Up

Deck Down Lip Up

Lip Down Individual push button switches

Deck size

2000 x 2700mm

Working range

Above 300mm below 250mm

LOADING / UNLOADING

Dock Leveller from ‘JAY’ are also widely used for loading/unloading of material from rucks / containers. This equipment becomes the bridge between the vehicle and the floor. This equipment are designed to flush with floor level when installed in pit.

FEATURES

Heavy duty and study equipment to give maximum output

1.Heavy duty structure

2.Anti-skid chequered plate for safety 3.Excellent smooth operation

4.Safety overload protection

5.Safety stand for maintenance

6.Rubber bumpers

Stainless Steel Stackers

"Customization”

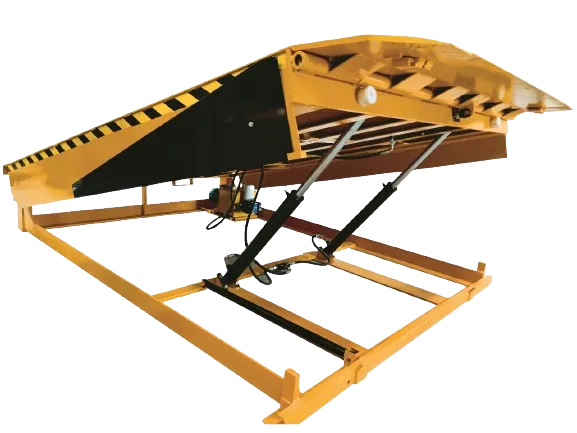

LOADING / UNLOADING

The edge of dock leveler is designed for applications when the dock and truck bed are close to the same height. The unit primarily bridges the gap between the dock and truck bed. The operating range compensates for small differences from the truck suspension during loading and unloading procedures.

STANDARD FEATURES

1.Edge-of-Dock Levelers an operating range of 5"above and 5" below deck,

2.Formed, plate steel Bump Blocks and steel faced moulded cord Rubber Bumpers protect dock face and Leveler from truck damage.

3. Torsion Spring Design allows simple, precise adjustment.

4.Leveler raises and extends smoothly onto truck bed with use of convenient Bar Handle.

5.Unit is easily recycled with truck in position and automatically returns to stored position upon truck departure

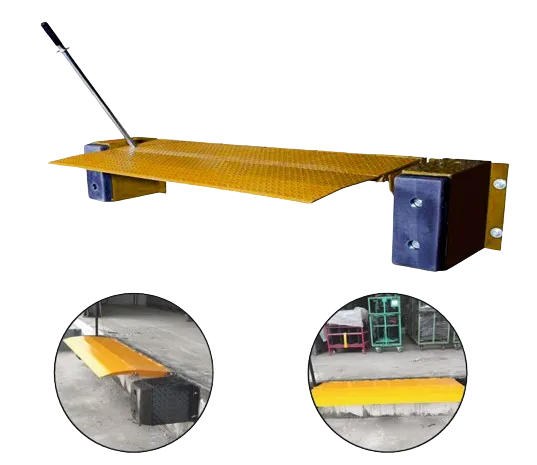

MDR 10 - Mobile Dock Ramp AN UNBEATABLE PERFORMANCE

PRODUCT OVERVIEW

Hydraulic Mobile Dock Ramp MDR 10 are designed to provide maximum productivity for Container / Truck loading / unloading operation. With the help of this equipment forklift can go right inside the container for loading / unloading of material and helps in reducing manpower and reduce damages.

• The equipment is manufactured with heavy robust structure to provide maximum safety during operations. Hydraulic Mobile Dock Ramp are mobile equipment which can be moved to free loading space once the work is completed.

• MDR 10 - Hydraulic Mobile Dock Ramp are equipped with hydraulic cylinder for aligning the height with container truck for smooth and easy operations. The equipment is also provided with floor locks for extra safety.

ORDER PICKERS

Manual Electric Order Picker from ‘MHE SERVE ’ are widely used in warehouses where order picking from racking is necessary. It is available in semi battery operated lifting and lowering model. It is ideal for the operator for quick and easy retrieving of goods. Lifting and lowering is done simply at the push of a button from the remote pad inside the operator cabin. Moving the machine around is done by pushing it manually. This range of SOP - is also available in A.C. version, with flameproof electricals and with customisation as per applications requirements. This range of equipment from MHE SERVE are very useful across all segments of industries.

SPECIFICATIONS

Max. Platform size : (LxW) 600 x 600 /900/900

Lowered platform height : 630 mm

Max. Raised height : Upto 4500 mm

Controls : DC / Push Buttons

FEATURES

Compact and useful equipment for order picking.

1.In-built battery charger

2.Swivel wheel for easy maneuverability

3.Robust chassis

4.Battery indicator

Scissor Lift Manufacturers In Thailand

Robust Construction:

Scissor lifts are built with high-strength steel and durable materials to ensure long-lasting performance and stability. The robust construction allows them to handle significant weight capacities and operate reliably in various environments.

Safety Mechanisms:

Safety is a top priority in scissor lift design. Manufacturers incorporate multiple safety features, including safety rails, emergency stop buttons, overload protection, and fail-safe hydraulic systems. These features ensure the safety of operators and prevent accidents during operation.

Versatility:

Scissor lifts come in a variety of sizes and configurations to suit different applications. From compact, low-profile models for indoor use to larger, heavy-duty models for outdoor and industrial tasks, these lifts provide versatile solutions for various height and load requirements.

Ease of Operation:

Modern scissor lifts are equipped with intuitive controls that allow for precise and easy operation. Features such as joystick controls, automatic leveling, and smooth hydraulic systems enhance operator comfort and productivity.

Mobility:

Many scissor lifts are designed for easy mobility, featuring wheels or tracks that enable movement across different surfaces. This mobility allows for quick repositioning and efficient use across various work areas.

Customization Options:

To meet specific needs, manufacturers offer customization options such as different platform sizes, load capacities, and lifting heights. Additional features like extendable platforms, non-marking tires, and specialized attachments can also be included.

Importance of Choosing the Right Scissor Lift Manufacturer

Selecting the right scissor lift manufacturer is crucial for ensuring the equipment’s reliability, safety, and performance. Reputable manufacturers adhere to stringent quality standards and use high-grade materials and advanced engineering practices. They also provide comprehensive support services, including installation, maintenance, and after-sales service, ensuring the scissor lift remains in optimal working condition throughout its lifespan.

Conclusion

Scissor lift manufacturers play a critical role in providing reliable and safe lifting solutions for various industries. By focusing on robust construction, advanced safety mechanisms, versatility, ease of operation, mobility, and customization options, these manufacturers deliver high-quality scissor lifts that enhance productivity and safety. Businesses should prioritize partnering with experienced and reputable manufacturers to ensure they receive tailored scissor lift solutions that meet their specific operational needs, thereby improving efficiency and safety in elevated work tasks.

JOIN MHE serve

Part to be our service.

# 54/1, Ichangur Village, Attibele Industrial Area Anekal Taluk, Bengaluru - 562107

© 2023mheserve. All Rights Reserved.