Conveyors / ESD Work Table

The Highly Efficient Loading / unloading / logistics Sorting and Conveying Materials. MHE Serve belt conveyor system can meet with you and determine which type of conveyor system will be most suitable for your needs.

PVC Belt Conveyor

Modular Conveyor

Inclined Belt Conveyor

Gravity Roller Conveyor

Motorized Roller Conveyor

Flexible Gravity Roller Conveyor (Extendable)

TO SOLVE AND ACHIEVE

Flexible Motorized Roller Conveyor is an extendable powered automatic roller conveyor with controllable conveying speed & direction and adjustable supporting leg height. Having enough power supply by one mini motor per section, it is well qualified to intensively transport goods especially with flat bottom in the warehouse/storehouse, workshop, factory, harbor, dock, etc. In addition, it can be applied to such situations as production-packing line, temporary conveying line and goods distribution line. It satisfies the easy, quick and efficient goods delivery. The flexible roller conveyor series has many styles to meet the diversified needs of customers. MHE SERVE factory has the ability to meet different needs. We can provide you with the difference types and specifications roller conveyor

Flexible Gravity Roller Conveyor (Extendable)

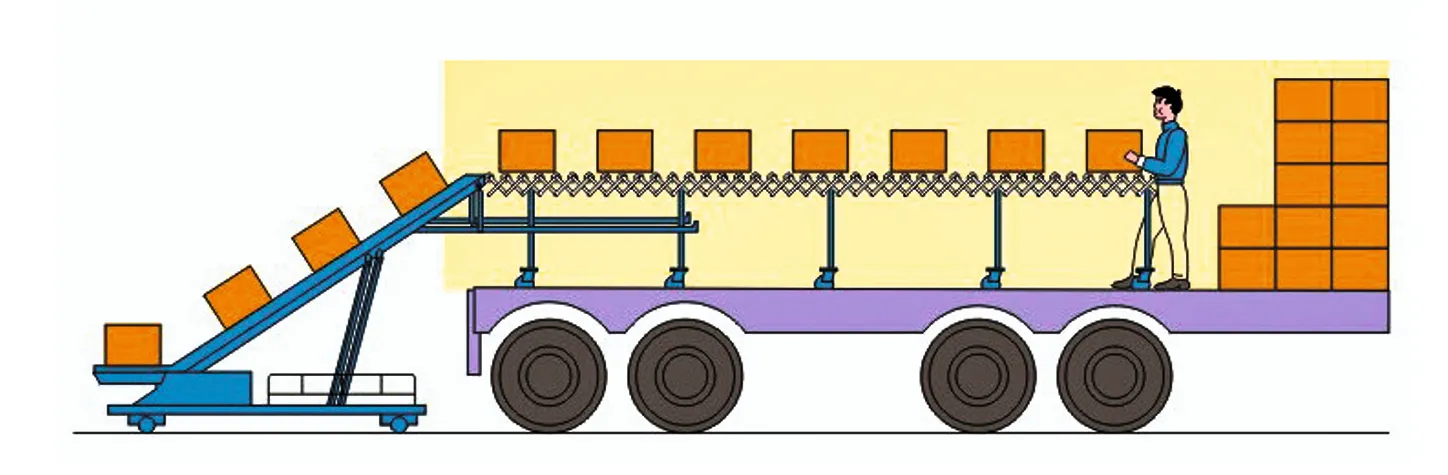

Loading and Unloading Belt Conveyor with Operator Platform

Portable belt conveyor designed with front operator platform for loading unloading from vehicles. The whole conveyor is movable on PU castors and can work in two directions:forward and backward. With adjustable speed and height.

Conveyors

The portable and adjustable truck loading conveyor belt system is a highly efficient solution for streamlining the process of loading and unloading goods from trucks. With its portable design, this system can be easily moved and positioned as needed, providing unparalleled flexibility in warehouse and distribution center environments. Its adjustable features enable seamless adaptation to various truck sizes and loading requirements, ensuring smooth and efficient material handling operations. Equipped with a durable conveyor belt, it offers reliable and continuous transportation of goods, enhancing productivity and reducing manual labor. This innovative system is a versatile and practical choice for optimizing truckloading processes across diverse industries.

Leading Conveyor Manufacturers in Bangkok

Thai Conveyors Co., Ltd.

Thai Conveyors Co., Ltd. is a prominent local manufacturer specializing in a wide range of conveyor systems. They offer customized solutions tailored to specific industrial needs, including belt conveyors, roller conveyors, and modular conveyors. Known for their high-quality products and reliability, Thai Conveyors ensures efficient and seamless material handling for various applications.

Durable Construction:

Conveyor systems are built with robust materials such as steel, aluminum, and high-quality polymers to ensure durability and long-term reliability. This construction is designed to withstand heavy loads, continuous operation, and harsh industrial environments.

Variety of Conveyor Types:

Manufacturers offer a wide range of conveyor systems to meet diverse needs, including belt conveyors, roller conveyors, chain conveyors, and modular conveyors. Each type is suited for specific applications, from transporting lightweight packages to moving heavy industrial materials.

Customization Options:

Conveyor systems can be customized to fit specific operational requirements. Manufacturers provide options for different lengths, widths, load capacities, and configurations. Custom features such as adjustable speeds, automated controls, and specific material handling capabilities are also available.

Advanced Technology:

Modern conveyors are equipped with advanced technologies such as automation, sensor integration, and smart controls. These features enhance efficiency, allow for real-time monitoring, and provide precise control over the material handling process.

Energy Efficiency:

Energy-efficient designs are a priority for conveyor manufacturers. By incorporating energy-saving motors and optimizing system designs, manufacturers ensure that conveyor systems consume less power while maintaining high performance, which reduces operational costs and environmental impact.

Importance of Choosing the Right Conveyor Manufacturer

Selecting a reputable conveyor manufacturer is crucial for ensuring the quality, reliability, and efficiency of the conveyor system. Experienced manufacturers adhere to strict quality standards and use high-grade materials and components. They also provide comprehensive support services, including system design consultation, installation, maintenance, and after-sales service, ensuring the conveyor system operates optimally throughout its lifespan.

Conclusion

Conveyor manufacturers play a vital role in enhancing material handling efficiency across various industries. By focusing on durable construction, a variety of conveyor types, customization options, advanced technology, energy efficiency, and safety features, these manufacturers deliver high-quality, reliable conveyor systems. Businesses should prioritize partnering with experienced and reputable manufacturers to ensure they receive tailored conveyor solutions that meet their specific needs, thereby improving productivity and operational efficiency.

JOIN MHE serve

Part to be our service.

# 54/1, Ichangur Village, Attibele Industrial Area Anekal Taluk, Bengaluru - 562107

© 2023mheserve. All Rights Reserved.